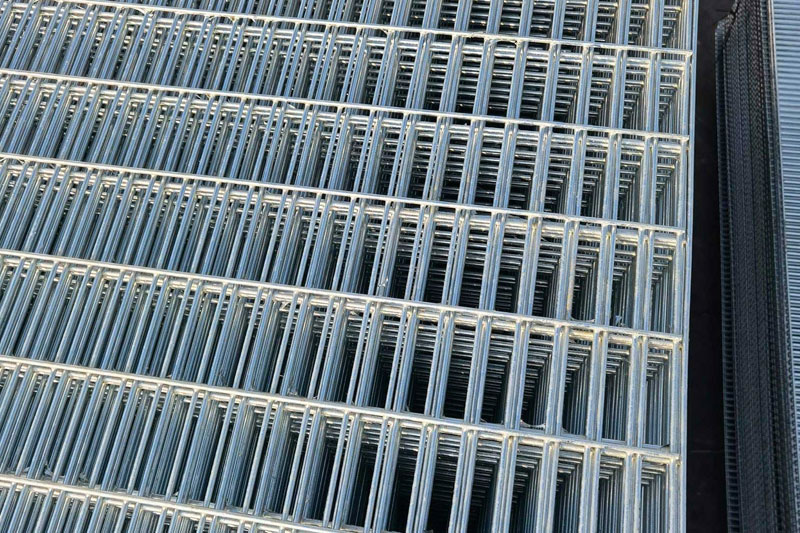

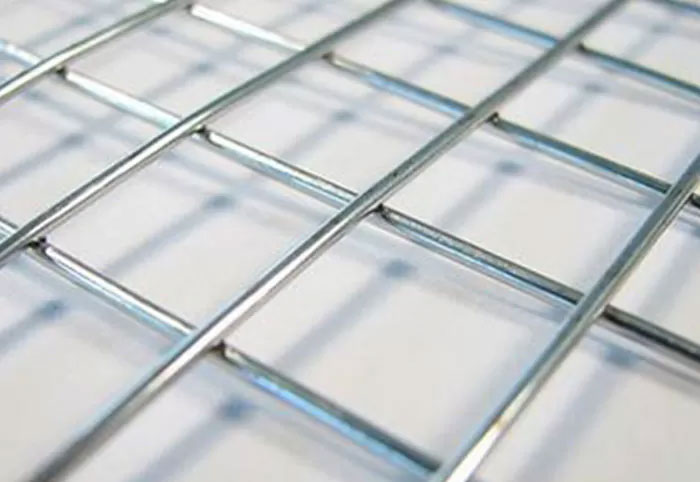

Welded Wire Mesh Panel

Welded galvanized metal mesh panels can be used to protect curtain openings, fan openings and other areas in hog barns that need additional protection from access to or damage by animals. These panels can also be used for outdoor penning and other confinement needs

• Galvanized

• Perfect for keeping animals confined to its intended space

• Keeps unwanted animals or predators out

Plastic coated welded wire mesh is widely used in industrial, road protect and house decorative. plastic coated welded wire mesh can be different colour, also can customize according your request. Colour card (RAL number) is the standard. In order to give you an exact colour, your can tell us the RAL number.

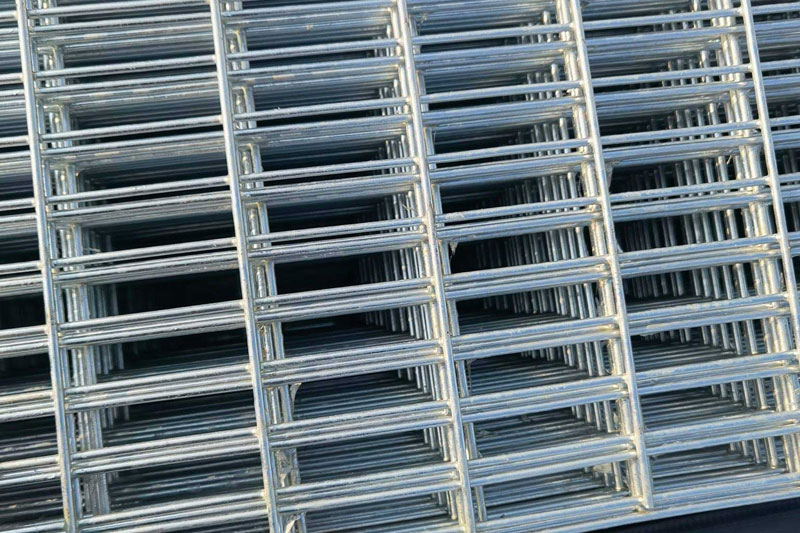

Specifications

The following are some specifications that we often export, for reference only, if you have special requirements, we can customize, we will have professional designers to provide you with the most satisfactory style.

Specifications:

Note: Special size and specifications can be made according to customers requires.

Item Name | Welded Wire Mesh Panel |

Material | Carbon steel Q195, Q235, A36 |

Surface Treatment | Galvanize or Stainless steel or PVC coated |

Type | Welded Mesh |

Length | 4ft,5ft,6ft,8ft,10ft,etc |

Diameter | 1mm-8mm |

Delivery time | 20 working days after receiving the advance payment |

Application | Architecture;decoration;components;household |

Note: Special size and specifications can be made according to customers requires.

Technology

The technology behind welded wire mesh panels involves a precise and controlled manufacturing process:

Wire Selection:

High-quality steel wires are selected based on the intended application and required strength of the mesh panel.

Wire Straightening:

The wires are straightened to remove any bends or kinks, ensuring uniformity and smoothness in the final mesh panel.

Welding Process:

The straightened longitudinal and cross wires are welded together at their intersections using electric resistance welding or spot welding techniques.

Mesh Panel Formation:

The welded wires are then assembled into a flat panel structure under controlled conditions to maintain accuracy and consistency.

Mesh Finishing:

After welding, the mesh panels may undergo processes like galvanization (for corrosion resistance) or powder coating (for added durability and aesthetics).

Quality Control:

Stringent quality checks are performed throughout the manufacturing process to ensure the mesh panels meet industry standards for strength, dimensions, and weld integrity.

Customization:

Welded wire mesh panels can be customized in terms of wire gauge, mesh size, panel dimensions, and coatings to suit specific project requirements.

The precision and efficiency of the welding process, along with the quality of materials used, contribute to the durability, strength, and versatility of welded wire mesh panels for various applications.

Application

Our welded wire mesh panels are galvanised to give them a protective coating, shielding them from corrosion and rust. These panels can be used for a wide range of applications, including:

· Security cages

· Dog fencing

· Animal enclosures

· Aviaries

· Bird cages

· Pet hutches

· Cat fences

· Pond covers or protection

· Garden fencing

Inquriy

If You Have Any Needs for Our Products

Please contact us no any hesitate. Our professional staff will contact you immediately and give you the most professional product acceptance and the best procurement plan. We sincerely welcome your inquiries